Background

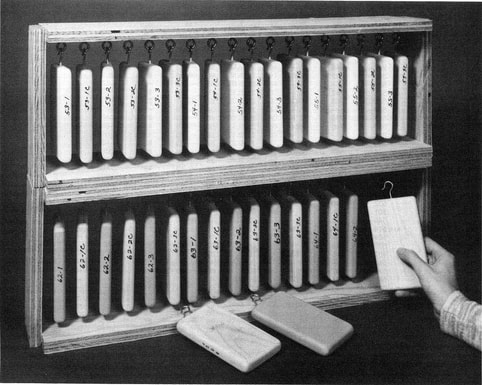

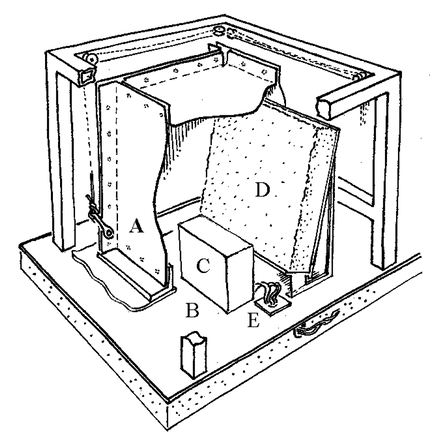

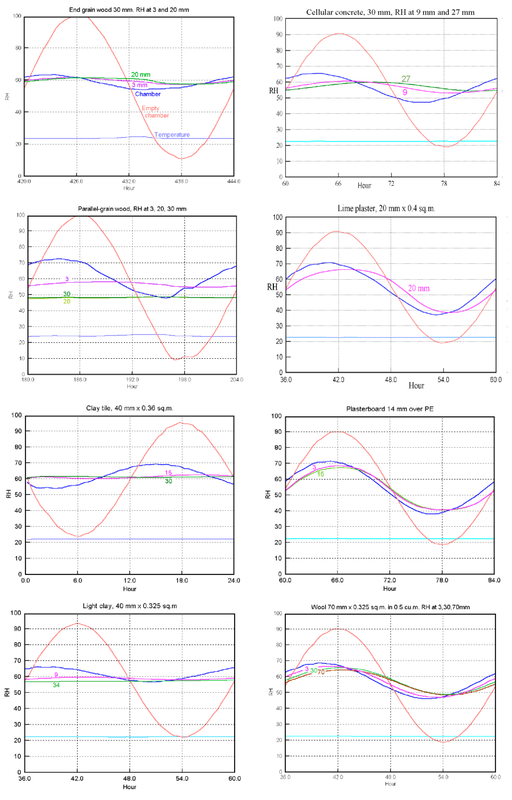

Padfield tested a wide variety of wall constructions in his flux chamber, including walls made of wood, clay tiles, unfired bricks, lime plaster, gypsum plaster, cellular concrete, and wool insulation. These tests revealed that "the best buffer of all is wood cut across the grain" (Padfield 1998, 59). A specially prepared mixture of bentonite clay and perlite was also found to perform quite well.

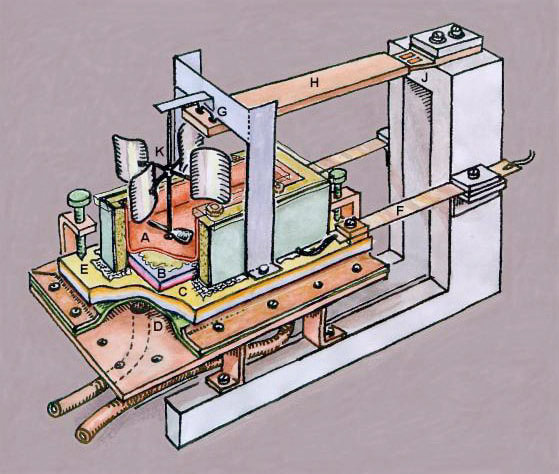

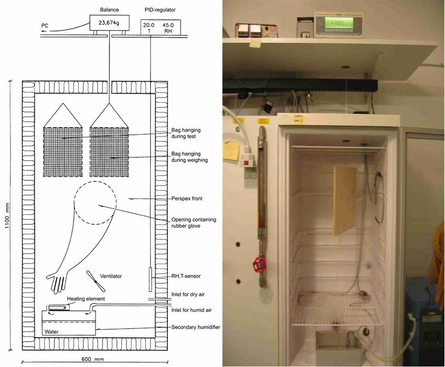

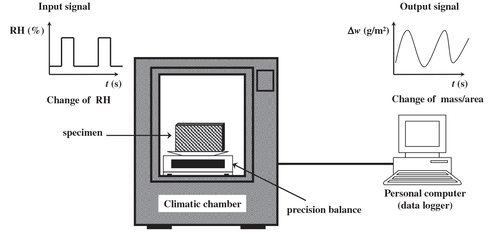

The testing protocol for MBV specifies that material samples should be sealed on all but one or two sides and exposed to a minimum of three cycles consisting of 8 hours of high humidity followed by 16 hours of low humidity. This asymmetric cycle is meant to replicate the conditions observed in a “typical” room, such as a bedroom or office, in which the respiration and perspiration of its human occupants increases the humidity for approximately 8 hours each day. The test should be carried out at 23°C with the high portion of the cycle at 75% relative humidity and the low portion at 33% relative humidity.

Sources

Feist, William C, James K Little, and Jill M Wennesheimer. December 1985. “The Moisture-Excluding Effectiveness of Finishes on Wood Surfaces.” https://www.fpl.fs.fed.us/documnts/fplrp/fplrp462.pdf.

Padfield, Tim. 1998. “The role of absorbent materials in moderating changes of relative humidity.” PhD Thesis, Technical University of Denmark. https://www.conservationphysics.org/phd/phd-indx.html.

Ramos, N. M. M., J. M. P. Q. Delgado, and V. P. de Freitas. 2010. “Influence of Finishing Coatings on Hygroscopic Moisture Buffering in Building Elements.” Construction and Building Materials, Special Issue on Fracture, Acoustic Emission and NDE in Concrete (KIFA-5), 24 (12): 2590–97. https://doi.org/10.1016/j.conbuildmat.2010.05.017.

Rode, Carsten, Ruut Peuhkuri, Kurt K. Hansen, Berit Time, Kaisa Svennberg, Jesper Arfvidsson, and Tuomo Ojanen. June 2005. “Moisture buffer value of materials in buildings.” Proceedings of the 7th Symposium on Building Physics in the Nordic Countries 1 (June 2005): 108–115.

Proposal |

Background |

Construction |

Methodology |

Results |